Services

ELECTRICAL CONSTRUCTION

- Complete excavation and installation of underground duct banks

- Penn Dot approved for road crossings

- All excavation equipment kept on hand

- Direct bury, concrete encased

- Commercial / Industrial lighting

- Emergency lighting

- Power Distribution

- Fire alarm and security systems

- Emergency power and generators

- UPS systems

- Instrumentation

- Data highway wiring

- Conduit systems for all electrical devices

HIGH VOLTAGE & LINE CONSTRUCTION

Throughout the years our Engineering department has designed and built many sub-stations and pole lines for private industry. We have also performed various types of maintenance and emergency repairs. We will respond to any electrical emergency, any day of the year, any time of day. Our engineering staff is capable of handling even the most difficult design and build projects.

While working with utility companies we have gained a vast amount of experience with underground systems, pole line replacements, substations, transmission lines, and storm related outages.

B.J. Baldwin Electric Inc:

- Is PennDOT approved

- Has been PP&L approved for twenty years

- Has an outstanding safety record

- Follows all ANSI and OSHA guidelines for rubber goods, hot sticks and bucket trucks

Projects typically handled by our high voltage department include:

- Trenching and Duct Banks

- Underground Duct Banks

- Pole Line Design, Installation and Maintenance (Energized & De-energized)

- Pole Replacements (Energized & De-energized)

- Cable Locating (Energized & De-energized)

- Re-conductoring (Energized & De-energized)

- Phase Rotation Verification (up to 34kV)

- High Voltage Cable Splicing and Termination

- High Potential Testing & Fault Locating

- Service Calls

- Substation Installation and Maintenance

- Installation, Maintenance, and Testing of Power Distribution Systems

- Installation, Maintenance, and Testing of Grounding Systems

- Installation, Maintenance, and Testing of Transformers and Switch Gear

- Protective Relay Calibration and Testing

- Fault Locating

- Planned Maintenance Programs

- Meter Calibration

- Complete Test Reports & Record keeping

ENGINEERING

B.J. Baldwin Electric, Inc.'s Engineering Department consists of Electrical Designers and Degreed Engineers and Licensed Professional Engineers. With diverse backgrounds in consulting, automation and constructions, the department offers versatile turn-key solutions.

The Engineering Department strives to aid owners, general contractors and other engineering professionals through cost-effective Engineering Systems & Support, and Communications & Project Management.

From initial concept and design to pre-construction planning and installation, our Engineering Department plays a vital role in managing the complexities of the construction process. We provide unmatched service and support that keeps projects on schedule and within budget

Projects frequently handled by our engineering department include:

ELECTRICAL

- Electrical Power Distribution Design

- Arc Flash Evaluation to comply with NFPA-70E

- Short Circuit Study and Relay Co-ordination Study

- Sizing Electrical Equipment

- Lighting & Branch Circuit Design

- Emergency Power Systems

- Fire Alarm & Security Systems

- Electrical Submittal Packages Review

- Auto CAD Drafting Services

- Application & Programming of Variable Frequency Drives and Soft Starters

- Power Quality Analysis - Harmonic Mitigation

- Evaluation and Mitigation of Plant Surges

- Design, Build and Startup Support

CONTROLS

- Control System Engineering - PLC Programming, HMI Configuration and Screen Development

- Sequel Server Data Base and Report Generation

- Control & Instrument Design/Interface

- Design, Build and Startup Support

- Industrial Plant Network Communication

PANEL ASSEMBLY & CONTROL SYSTEM DESIGN

B.J. Baldwin Electric, Inc. has the experience and expertise to provide complete control systems for a wide variety of applications in any given industry.

Our services include:

- Custom control panel design and fabrication

- PLC software development

- Machine Automation

- HMI-Operator Interface programming

- Factory automation & Monitoring

- Servo system programming

- Auto CAD based diagrams and documentation

- Custom variable frequency drive packages

We can also provide:

- UL (Underwriters Laboratories Inc

- A wide variety of NEMA rated panels

- Intrinsically safe & explosion proof

- Retrofitting and upgrading existing panels

- Installation services, start-up services, and customer training

We have the capabilities for total turnkey projects from initial concept, through hardware and software design, to installation and documentation. Our control engineering staff is well trained and experienced in programming techniques and is well versed in the all of the current PLCs and Operator Interfaces.

Our Panel Assembly and Control System Design Team has over a half a century of combined man-years of controls and automation.

SUBSTATIONS

B.J. Baldwin Electric, Inc. ranks among the premier substation contractors in Pennsylvania with our qualified professional employees, competitive pricing, and on-time completions.

Our qualified field crews are made up of individuals with the following skills specific to the substation industry;

- Engineering

- Design and drafting

- Concrete construction

- Structural steel erection

- Aluminum bus installation

- Trenching

- Control wiring

- Site work

- Backfilling

- Conduit and wire installation

- High-voltage switch installation and adjusting

B.J. Baldwin Electric, Inc.'s substation construction and maintenance services include the following:

- Complete engineering, procurement and installation of substation facilities including all over and underground transmission and distribution facilities.

- Setting and calibration of electro-mechanical, solid state, static and microprocessor controlled relays.

- Breaker and switch replacements.

- Energized and de-energized cable locating.

- Verify phase rotation (up to 34kV).

- Planned maintenance programs.

- Power line carrier installation and testing.

- Installation and testing of all metering devices.

- Transformer and switchgear inspections and testing.

- Protective relay calibration and testing.

- Complete test reports and record keeping.

Substation designed, built and erected by B.J. Baldwin Electric, Inc.

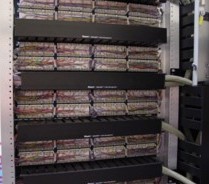

NETWORK SERVICES

Whether you need voice, data or video communications, our professional staff of engineers, project managers, specialists, technicians and installers will take you through your project from consultation and design through complete installation.

Our networking services include the following:

- Network infrastructure design

- Intrabuilding and interbuilding copper and fiber optic systems

- Underground and aerial construction — copper and fiber optic systems

- Voice/data/video cabling systems

- Testing and documentation

- Fiber optic installations

- Fusion splicing and testing — Single mode & Multimode

- OTDR testing

- dB Loss testing & reporting

- RCDD services available upon request

- Inside and outside cabling

- Lashing

- Trenching

- Pole line construction

- Cat5 Wiring & Testing

- Access to PBX & Key telephone systems

Baldwin Network Services is a BICSI Corporate Member, and has partnered with the many manufacturers in order to provide warranted, certified and engineered installation solutions. For a complete list of manufacturers, please contact us.

From Nationwide multi-campus rollouts to single cable installations, our professional staff of design engineers, project managers, technicians and installers will handle your project from design through final testing

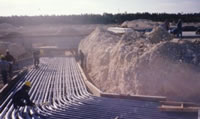

EXCAVATION & UNDERGROUND UTILITIES

B. J. Baldwin Electrical Inc. offers full excavation services for residential, industrial, commercial and agricultural clients. Our excavation experts can solve drainage problems and accomplish your earth moving needs. We manage large or small projects involving heavy equipment such as digging a foundation, pond, dry well, site development or trenching for under ground utilities. We specialize in grading tough terrain, utility runs and problem applications.

We are capable of providing equipment and operators to support the following project types.

- Drainage

- French drains

- Landscape construction

- Utility ditches

- Site development

- Site improvement

- Foundations

- Surface stabilizations

- Demolitions

- Land restoration

- Land clearing

- Catch basins

- In ground sewer systems

- Road construction

PREVENTATIVE MAINTENANCE & TESTING

With today’s businesses making substantial investments into high technology, preventive maintenance (PM) has become a key issue in preventing costly damages and repairs. As the old adage states, “an ounce of prevention is worth a pound of cure.” Our PM programs include thermo graphic inspections; enabling customers to save money by keeping their equipment in its best working condition.

Our Preventive Maintenance programs include:

- Bridge lighting

- Controller cabinets

- Emergency vehicle preemption systems

- High voltage potential testing & fault location

- Lighting systems (accent & navigational)

- Loop detection

- Protective relay calibration &testing

- Railroad crossings

- Site lighting

- Substation maintenance

- Telephone vaults

- Traffic management cameras

- Traffic management systems

- Transformer & switchgear inspections & testing

- Underground conduit systems

- A specialized portion of our PM programs include thermographic inspections

Other Preventive Maintenance services include the following:

- Circuit breaker testing

- Cleaning and repairing

- Ground fault system tests

- Ground resistance testing

- Infrared testing

- Insulating oil tests

- Maintenance of high voltage electrical systems – Overhead

- Maintenance of low voltage electrical systems – Overhead

- Motor and control center testing

- PCB surveys

- Start-Up services

- Underground buried cabling

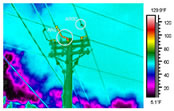

INFRARED SCANNING

Infrared scanning accurately identifies the presence of abnormal heat in electrical and mechanical systems, which can help predict equipment failure. Infrared scanning is a non-invasive procedure, which can be performed under normal plant conditions so that no shut down time is required.

The following are benefits to having your equipment scanned by B.J. Baldwin Electric, Inc.

Saves Money:

- Prevents equipment failures

- Reduces costly down time

- Improves electrical and mechanical efficiency

- Saves money on emergency repairs

Saves Time:

- Reduces emergency calls for maintenance crews

- Avoids disruption of services by using non-invasive technology

- Identifies and prioritize areas needing preventative maintenance

Improves Safety:

- Identifies fire hazards

- Reduces the risk of catastrophic system failure